Built for Utility

Throughout the entire packaging rebrand, my goal was to create a professional system that considered the many compliance and functional production aspects, delivering an end result that served the customers’ needs and further enhanced Hunter’s reputation for quality. The result is a B2B package identity system that flows seamlessly throughout every stage—from production to customer delivery and use. As we work to meet international compliance standards, the packaging may need to be updated, but thanks to the solid groundwork created at the beginning of the process, building upon the system is proving to flow smoothly.

Whether retail or B2B, the key objective in Hunter packaging is to provide the end-user with the information they need to make informed decisions. We researched the user experience in each market to identify the decision-making process for each market, balanced with compliance codes and guidelines as needed. A lengthy process that required the collaboration and input of many professionals with diverse specialties added to the success of the packaging project in the field.

The Rubber Grid

I developed a "rubber grid" to make it easier and faster for designers to maintain consistent placement and size ratios of typography and standard identity elements when creating new package layouts, regardless of unique package sizes. The rubber grid uses a 12-column system. Each column is further broken down into quarters for cases where further segmentation is needed. The first grid segment is broken into sixteenths to help size type.

The rubber grid may be stretched or compressed in any direction, but it must always start and end at each end of the package face being measured. This system allows designers to create packaging consistently and work quickly, without compromising the professionalism and brand integrity of the packaging design.

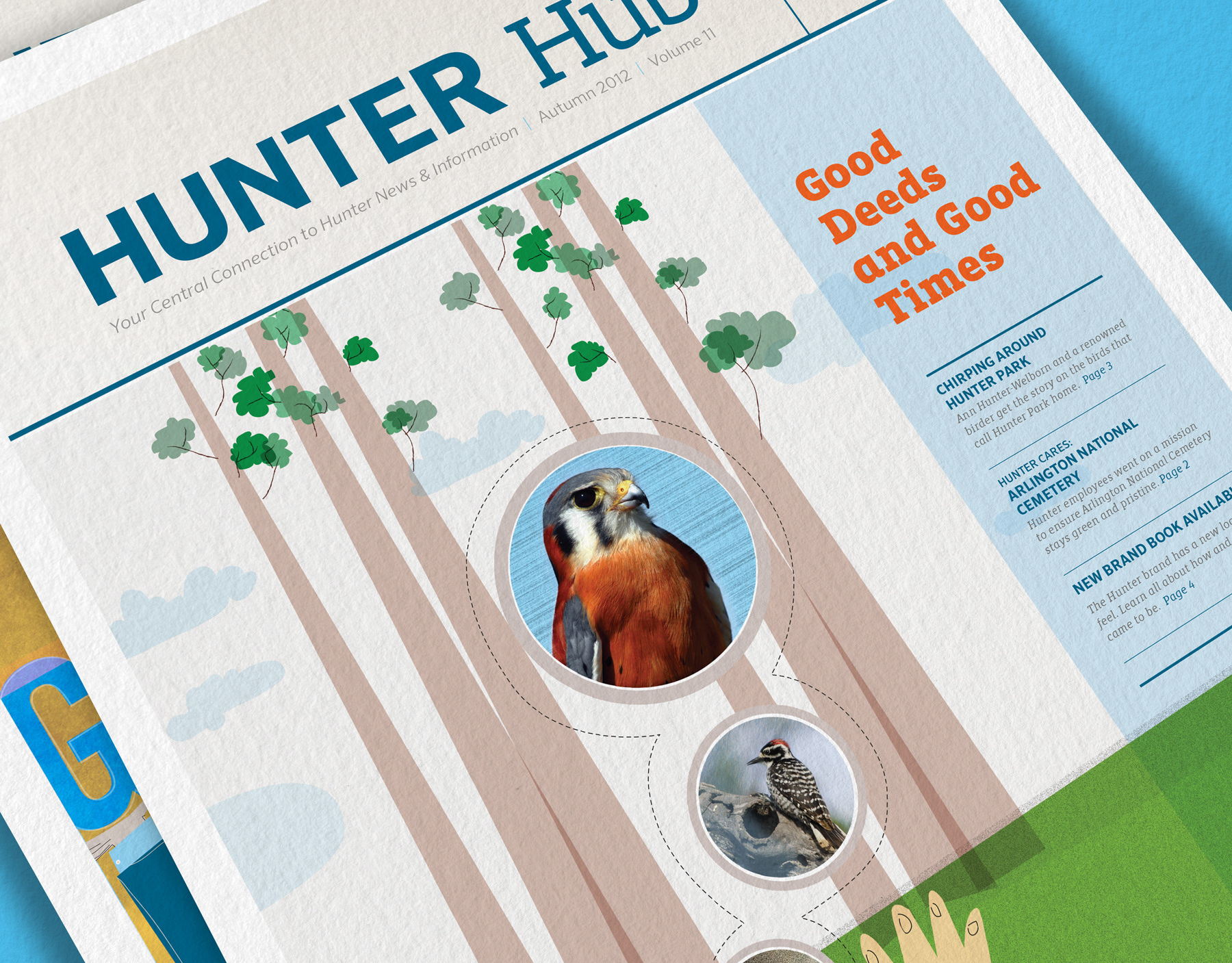

Master Cartons

All B2B packaging was built for utility first. Elements include a striking Hunter Blue band that wraps around the entire box that houses the Hunter logo—an industry stamp of quality. Hunter's tagline, Built on Innovation, appears clearly on each side. The final execution is clean, simple, and professional, but much care was taken into developing a system that worked for the many varying shapes and sizes of the 1000s of unique boxes that house over 37,000 SKUs. The success of this exercise was developing a solution that could be executed in mere minutes by a designer and would have a strongly identifiable branded component out in the field.

B2B Product Packaging

Hunter products are sold by irrigation distributors to a professional contractor customer. In most cases, the contractor knows the product and brand they want to purchase before entering their local distributor location. A goal of the packaging rebrand was to ensure the distributor staff pulled the correct product for their customer. The catalog number appears boldly on all sides of the packaging to aid easy identification. Under the catalog number is a brief product description as secondary confirmation that the right product is being provided to the customer. This was a necessary solution to solve slight variations in model numbers that could get quite complex for more sophisticated product offerings.

Maintaining a Consistent Scale in Typography

When sizing type throughout the package, designers always use the vertical grid sized for the package face. This helps the designer ensure that all type is scaled proportionally to each other throughout all the panels.

Bag art

Bag art is printed at a vendor off-site and delivered to Hunter Industries. Product labels are then created by Hunter’s manufacturing engineer team and printed and packaged in-house. I designed a labeling system that worked with the manufacturing engineers’ labeling software that maintained brand integrity throughout the packaging process.